Form and Function: Basket Molds Factory for Efficient Plastic Processing

China Sale Plastic Basket Molds Price Factory Manufacturer

In the world of plastic processing, innovation drives efficiency, and one critical component contributing to this advancement is the basket mold Factory. These specialized molds are used to create intricate and versatile plastic products, providing industries with an efficient way to manufacture a wide range of items. In this article, we will explore the unique characteristics of basket molds and how they have become essential for efficient plastic processing.

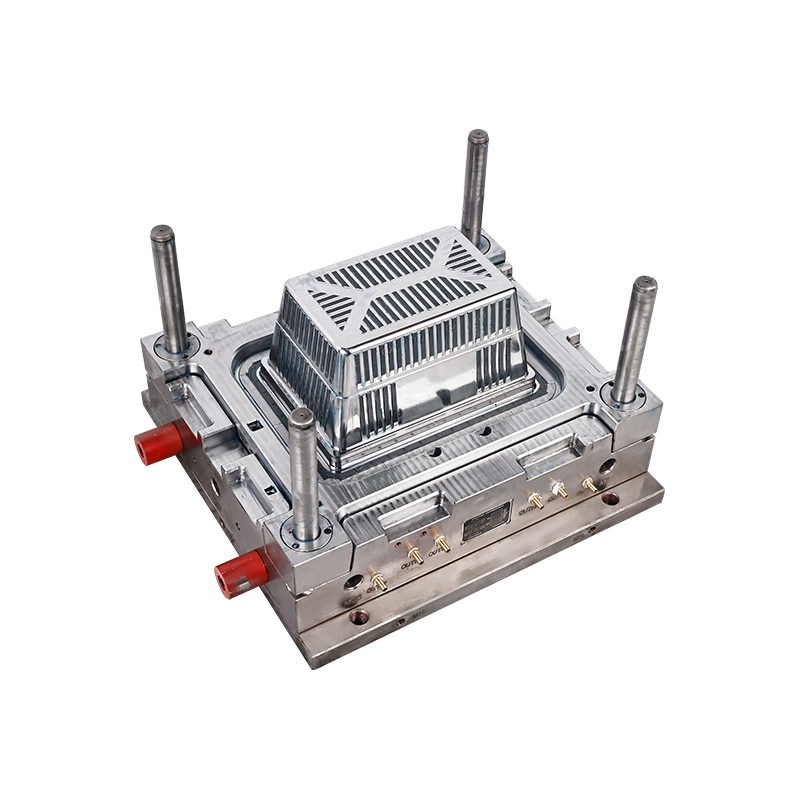

Basket molds Factory are a type of mold designed to create basket-like structures from plastic materials. They are typically used in injection molding, where molten plastic is injected into a mold cavity, then cooled and solidified to form the desired shape. Basket molds are characterized by their complex design, allowing for intricate patterns and openings, which makes them ideal for producing plastic baskets, containers, and other similar products.

Versatility in Design with Basket Molds Factory

One of the key advantages of basket mold factories is their versatility in design. These molds can create various shapes and sizes, from small storage baskets to large industrial containers. The ability to customize basket molds allows manufacturers to meet the specific requirements of their products, whether it's a specific pattern, size, or structural strength. This versatility is a significant reason why basket molds are widely used in different industries.

Efficiency in Plastic Processing with Basket Molds Factory

Basket molds are designed for efficient plastic processing, enabling manufacturers to produce high-quality products quickly. The mold's intricate design allows for even distribution of molten plastic, ensuring consistent wall thickness and structural integrity. This efficiency leads to reduced cycle times, allowing manufacturers to produce more units in less time. For industries that rely on mass production, such as consumer goods and packaging, basket molds are a valuable asset.

Applications of Basket Molds Factory in Different Industries

The applications of basket molds Factory span various industries, highlighting their importance in modern plastic processing. In the consumer goods sector, basket molds Factory are used to create storage baskets, laundry hampers, and other household items. In the food industry, they are used to produce baskets for carrying fruits and vegetables. Even in the automotive industry, basket molds play a role in creating parts like air filter housings and storage compartments. This wide range of applications demonstrates the versatility and efficiency of basket molds Factory.

The Role of Technology in Basket Molds Factory

Advancements in technology have greatly enhanced the capabilities of basket molds. With computer-aided design (CAD) and computer-aided manufacturing (CAM), manufacturers can create precise and complex mold designs. This technology enables the creation of intricate patterns and shapes that would be difficult to achieve with traditional methods. Additionally, the use of high-quality materials for basket molds Factory ensures durability and longevity, reducing the need for frequent replacements and maintenance.

Environmental Considerations with Basket Molds Factory

As industries focus on sustainability, basket molds Factory contribute to environmentally friendly practices. The efficient design of basket molds Factory minimizes waste during production, as excess plastic can be recycled and reused. Additionally, the durability of these molds Factory means fewer resources are required for replacement and maintenance. By using basket molds, manufacturers can reduce their carbon footprint and contribute to a more sustainable approach to plastic processing.

The Future of Basket Molds Factory

The future of basket molds Factory looks promising, with continued advancements in technology and materials. As the demand for customized and efficient plastic processing grows, basket molds Factory will play an increasingly important role in meeting these requirements. Manufacturers are exploring new materials and designs to create more durable and efficient basket molds, ensuring they remain at the forefront of plastic processing technology.

Basket molds have become an essential component in efficient plastic processing, offering versatility, efficiency, and durability. As technology continues to advance, basket molds are expected to become even more efficient, contributing to a more sustainable approach to plastic processing. With their unique characteristics and wide-ranging applications, basket molds are set to play a crucial role in the future of efficient plastic processing.

English

English  русский

русский Español

Español